HOME >> NEWS >> Industry News

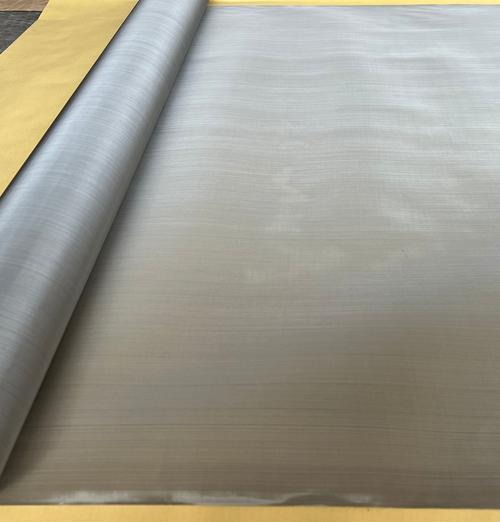

200 mesh stainless steel wire mesh, also commonly referred to as stainless steel wire cloth or stainless steel screening mesh, has a clear and specific definition based on its structural characteristics. By definition, within a range of one inch (equivalent to 25.4 millimeters), this type of mesh features 200 mesh openings both horizontally and vertically. This precise mesh density endows it with excellent performance, making it widely applied in various fields. Primarily, it is used for filtration, screening, and protection purposes. For instance, in industrial filtration processes, it can effectively separate impurities of specific particle sizes from liquids or gases; in the screening of granular materials such as chemicals and food additives, it ensures the uniformity of particle sizes; and in protection scenarios, it can serve as a protective layer for equipment or facilities to prevent the entry of small foreign objects.

In terms of weaving patterns, 200 mesh stainless steel wire mesh mainly adopts two common methods: plain weave and twill weave. Each of these weaving patterns has its own unique characteristics, which determine their respective application scenarios. Plain weave is a relatively simple and traditional weaving method, where the warp and weft wires intersect alternately one above the other. This weaving structure results in a tighter mesh surface, with small and uniform mesh openings. Due to its tight structure, plain weave 200 mesh stainless steel wire mesh has high filtration precision, making it suitable for occasions that require strict filtering effects, such as the filtration of precision electronic components cleaning fluids. In contrast, twill weave is formed by the warp wires passing over two or more weft wires and then under one or more weft wires in a regular cycle. This weaving method gives the mesh a certain degree of elasticity and flexibility. The twill weave mesh is not easily deformed when subjected to external forces, and it has good air permeability and water permeability while maintaining a certain mesh density. Therefore, it is more suitable for applications that require a certain degree of flexibility, such as the production of flexible filters in the medical device industry.

Next, let's focus on the issues of wire diameter and aperture, which are of great concern to most users. Theoretically, there is a corresponding relationship between the wire diameter and the aperture of 200 mesh stainless steel wire mesh. Specifically, when the wire diameter is 0.05 millimeters, the corresponding aperture is 0.077 millimeters; when the wire diameter increases to 0.06 millimeters, the corresponding aperture decreases to 0.067 millimeters. However, in actual production, due to the weaving process of the mesh, a certain degree of stretching will occur to the wires. This stretching phenomenon will cause the actual wire diameter to be slightly thinner than the theoretical value, and at the same time, the actual aperture will be slightly larger than the theoretical calculated value. It is important to note that this slight deviation between the actual and theoretical values is a normal phenomenon in the production process, which is caused by the physical changes of the wires during weaving and does not affect the overall performance and normal use of the 200 mesh stainless steel wire mesh.

WhatsApp

WhatsApp