HOME >> PRODUCTS >> Metal Filter Screen

Description: Mineral Screen Mesh is a newly developed product in the wire mesh industry. As a metal mesh structural component designed for screening and filtering, it is widely applied in operations such as screening, filtering, dehydration, and desliming. Below is a detailed overview of its features and classif

Model No.:JH576SM

Model No.:JH576SM Supply Nature:Factory Direct

Supply Nature:Factory DirectPRODUCTS

NEWS

Product Details

Mineral Screen Mesh is a newly developed product in the wire mesh industry. As a metal mesh structural component designed for screening and filtering, it is widely applied in operations such as screening, filtering, dehydration, and desliming. Below is a detailed overview of its features and classification.

1. Core Features of Mineral Screen Mesh

Superior Performance: Boasts high screening efficiency, strong wear resistance, corrosion resistance, anti-slip property, anti-vibration ability, high elasticity, excellent toughness, and no hole clogging.

Structural Advantages: The cross-section of the mesh wire is trapezoidal, with gaps narrow at the top and wide at the bottom—an design that enhances material separation.

High-Quality Manufacturing: Screen strips are made of cold-rolled stainless steel wires, while support strips are welded via automated mineral screen mesh production equipment. This ensures uniform screen gaps, stable welding quality, a high open area ratio, and long service life.

Versatile Rigidity: Possesses high strength, rigidity, and load-bearing capacity, allowing it to be fabricated into rigid screening/filtering devices of various shapes.

2. Classification of Mineral Screen Mesh

Mineral Screen Mesh covers multiple types to meet diverse industrial needs, including: Stainless Steel Welded Mineral Screen Mesh, Screen Plate & Screen Basket, Vibrating Screen Mesh, Slotted Screen Sheet, Cylinder Mesh, Curved Screen & Special-shaped Wire Mesh, High-strength Screen Mesh, and Polyester Mineral Screen Mesh. Key types are detailed as follows:

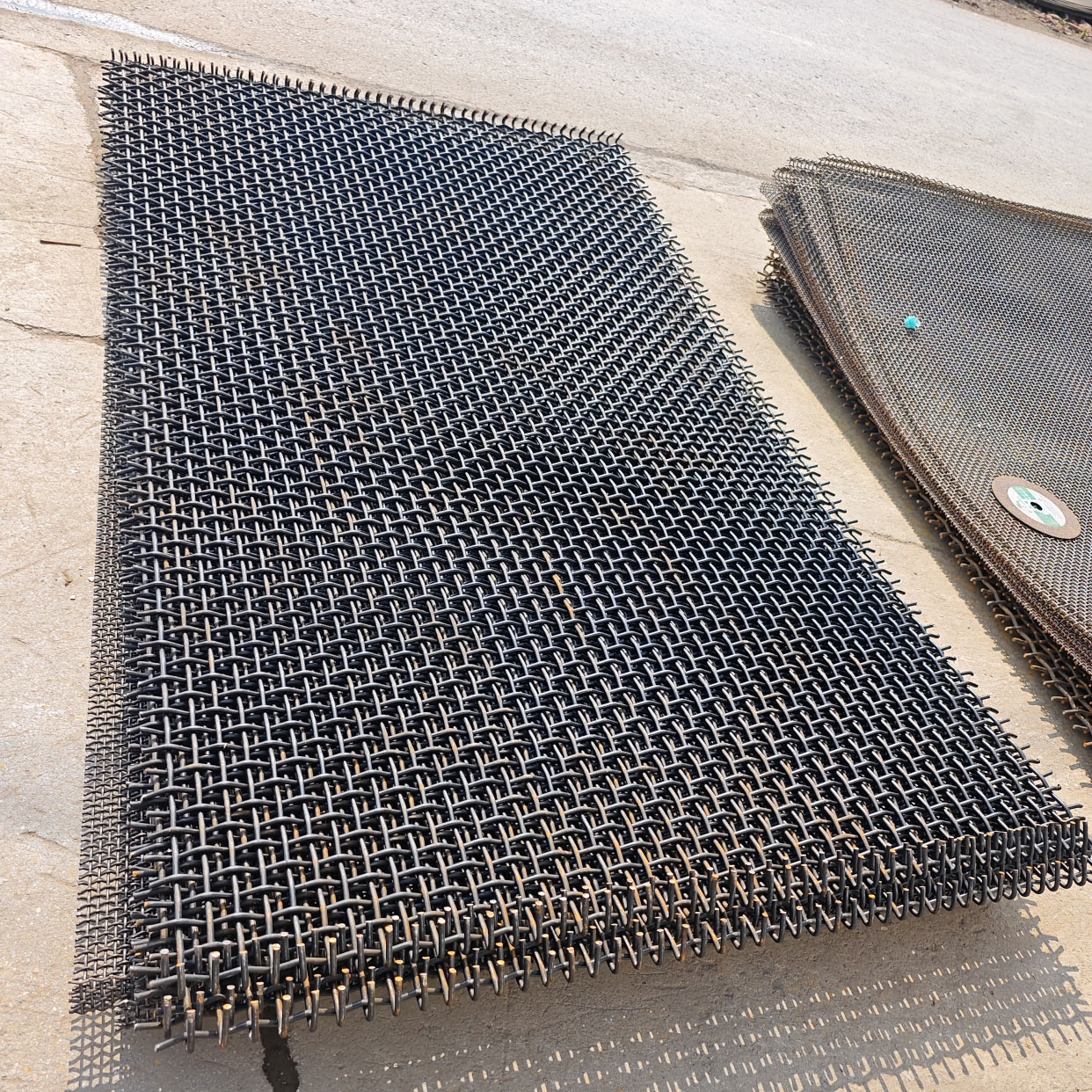

Screen Basket

Product Positioning: A newly developed product in the wire mesh industry.

Key Features: Easy permeation, wear resistance, and corrosion resistance; trapezoidal wire cross-section with narrow-top-wide-bottom gaps.

Materials & Specifications: Made of stainless steel or iron wire; square hole type; plate thickness ranging from 0.2mm to 8.0mm.

Applications: Widely used in mining, coal, petroleum, chemical fertilizers, grain, and environmental protection industries. It also serves as slotted screen mesh, petroleum filter mesh, and salt industry mesh.

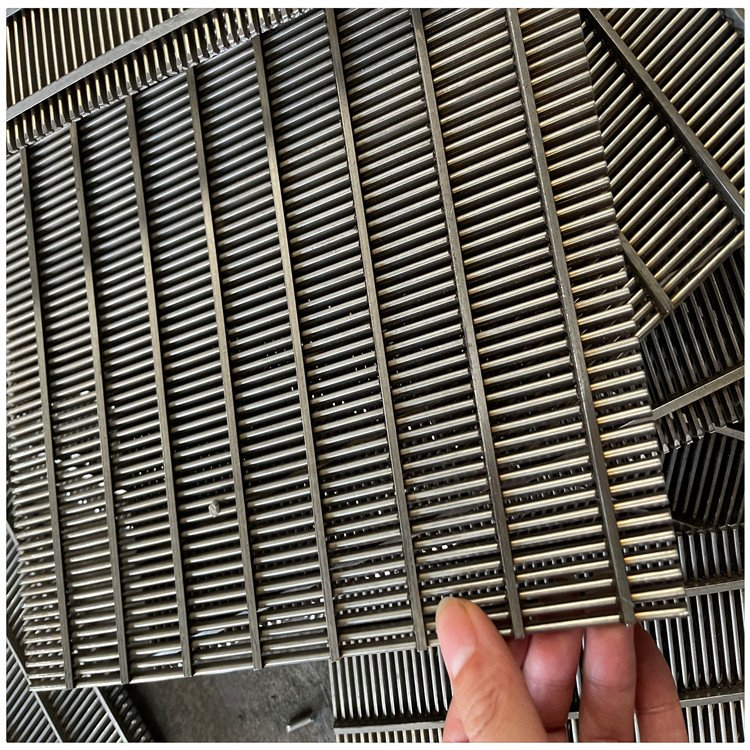

Curved Screen

Primary Uses: Mainly applied in coal preparation plants and mineral processing plants for pre-dehydration, desliming, medium removal of materials, and classified coal slime recovery. It can also be used with hydrocyclones for effective classification, dehydration, desliming, and medium removal of fine-grained materials.

Structural Features: Composed of screen panels with a wrap angle of 45° or 60° and a radius of curvature of 2030mm. The curved screen surface and frame adopt a pivot steering structure, enabling 180° rotation to extend the screen surface’s service life.

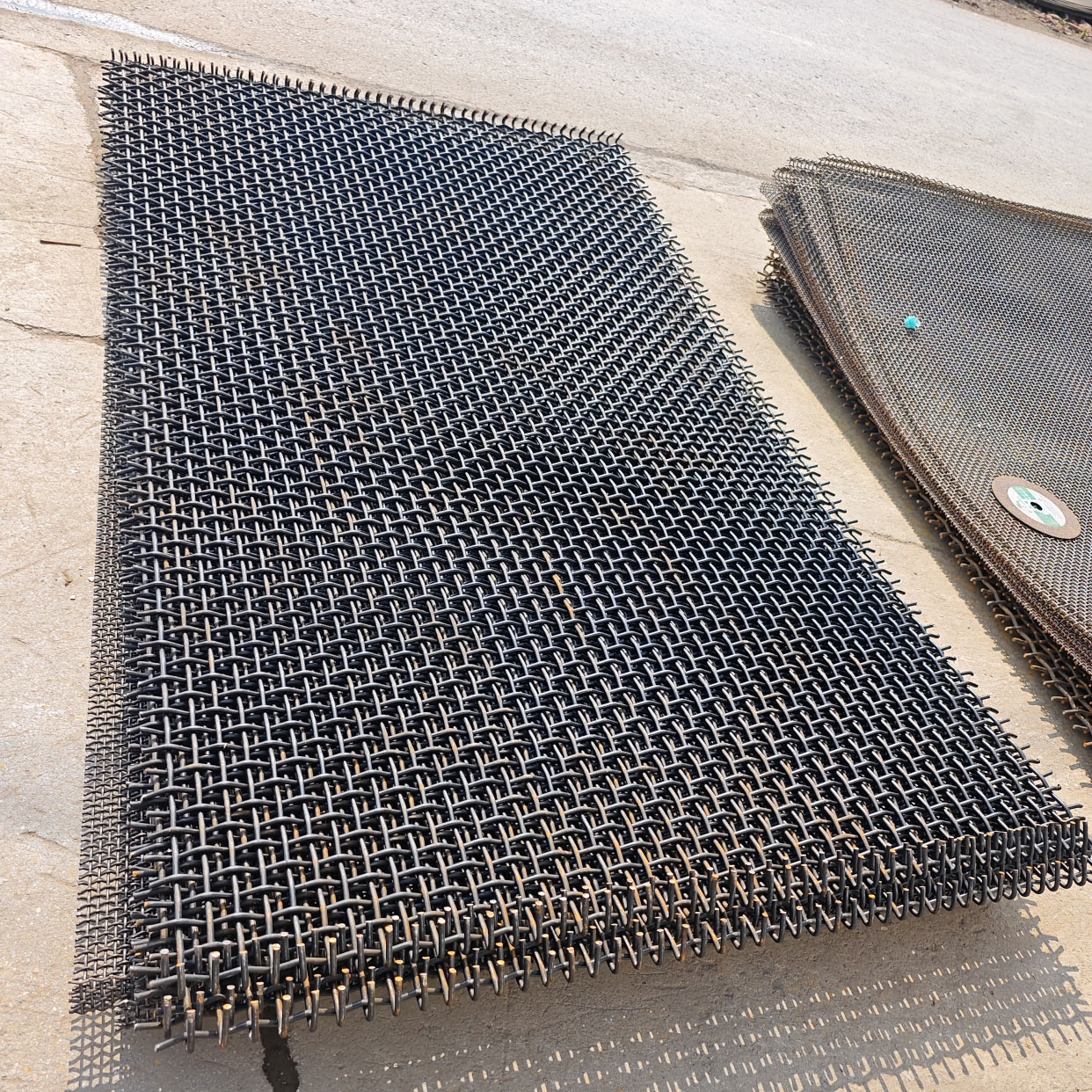

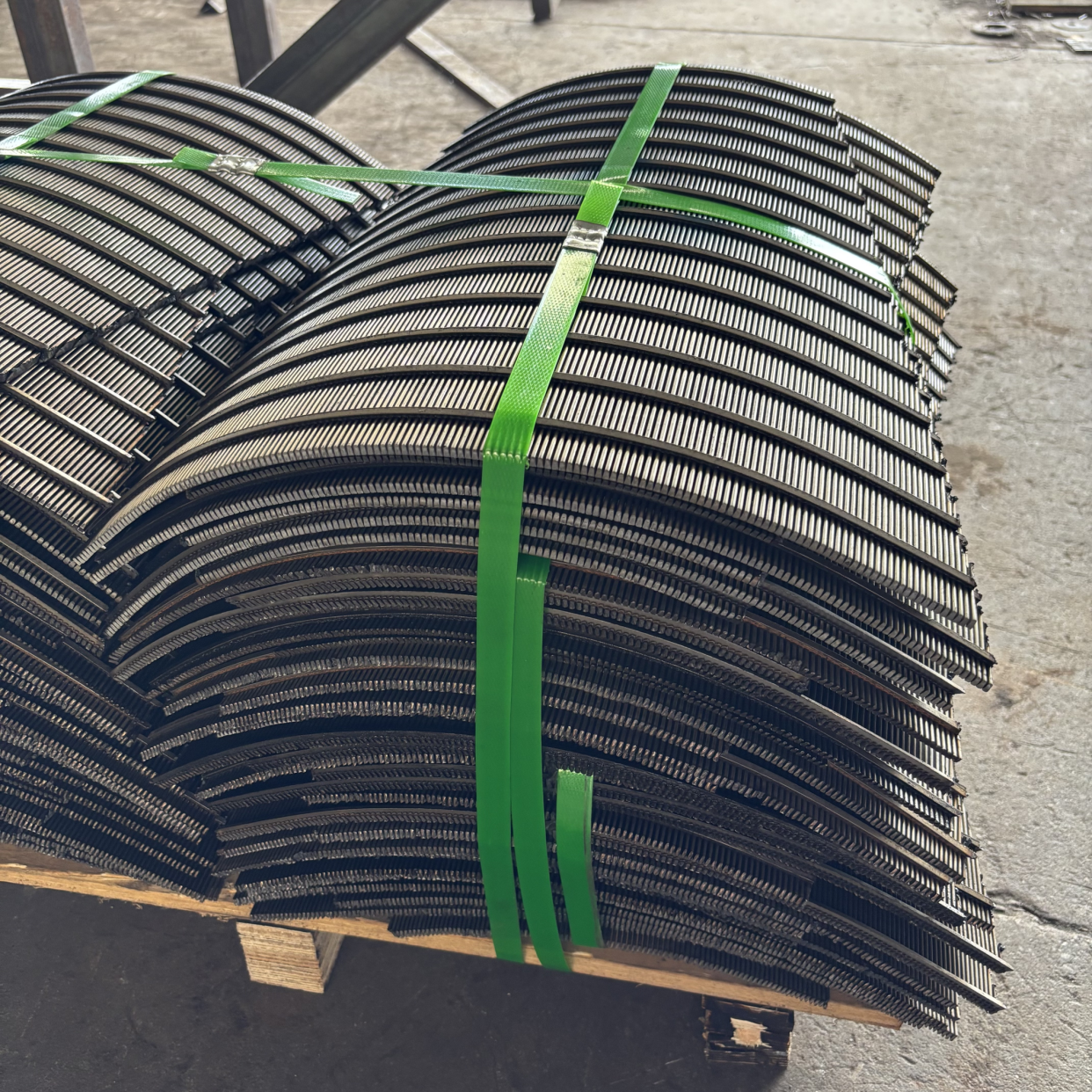

Crimped Wire Mineral Screen Mesh

Materials: Stainless steel wire, galvanized wire, black iron wire, low-carbon steel wire.

Advantages: High temperature resistance, acid resistance, alkali resistance, corrosion resistance, and wear resistance.

Weaving Methods: Adopts a "pre-bending first, then forming" process, including locked weaving, bidirectional plain weave, unidirectional corrugated weaving, bidirectional flat weaving, bidirectional corrugated weaving, and rectangular hole weaving.

Wide Applications: Used in mining, petroleum, chemical engineering, construction, mechanical accessories, protective mesh, packaging mesh, barbecue mesh, sintering furnace mesh, hardware mesh, handicraft mesh, vibrating screen mesh, food machinery mesh, infrastructure (highways, railways), etc. Suitable for solid material classification, liquid/slurry filtration, and civil use.

Polyurethane Mineral Screen Mesh

Application Scope: Polyurethane classification screen mesh and plates are widely used in screening machines for metallurgy, mining, coal, building materials, water conservancy, and road construction. They are ideal replacements for steel plate punching screen mesh, steel wire woven mesh, stainless steel screen plates, and rubber screen plates.

Outstanding Benefits: Light weight, high screening efficiency, no hole clogging, friction resistance, impact resistance, tear resistance, long service life (2-3 times that of stainless steel screen plates), low noise, easy installation, and high comprehensive benefits.

Product consultation

WhatsApp

WhatsApp