HOME >> PRODUCTS >> Wire Mesh >> Crimped Wire Mesh

Description: Our Mining Screen Mesh is a high-performance screening solution engineered for the rigorous demands of the mining, quarrying, and aggregate industries. Designed to handle difficult, irregular, and high-moisture materials,

Model No.:JH4668SM

Model No.:JH4668SM Supply Nature:Factory Direct

Supply Nature:Factory DirectPRODUCTS

NEWS

Product Details

Our Mining Screen Mesh is a high-performance screening solution engineered for the rigorous demands of the mining, quarrying, and aggregate industries. Designed to handle difficult, irregular, and high-moisture materials, this specialized mesh offers superior durability, efficiency, and reliability in sizing and classification applications. With advanced manufacturing techniques and premium materials, our screen mesh maximizes productivity and minimizes downtime in even the most challenging operational environments.

High Open Area & Efficiency: Precision-woven apertures maximize the working surface area, enabling higher throughput and improved screening efficiency for fine, wet, or plastic materials.

Excellent Self-Cleaning Effect: The unique crimped wire design reduces blinding and clogging, ensuring consistent performance and reduced maintenance.

Enhanced Durability: Constructed from high-strength materials with advanced crimping technology, our mesh offers exceptional resistance to abrasion, impact, and heavy loads.

Customizable Designs: Available in flat top, double crimp, and slotted configurations to meet specific material handling requirements.

Versatile Material Options: Carbon steel, stainless steel, and other alloy wires provide tailored solutions for corrosive, high-wear, or high-temperature applications.

Material: High-carbon steel, stainless steel (304/316), and other wear-resistant alloys.

Weaving Process: Advanced crimping and weaving techniques create precise, uniform apertures. Options include:

Slotted Flat Wire Mesh: Features indistinctly crimped flat wires for a flat working surface and enhanced resistance to heavy materials.

Slotted Crimped Wire Mesh: Uses crimped wires for added rigidity, improved material turnover, and reduced blinding.

Sizing and classification of ores, minerals, and aggregates

Coal processing and mining operations

Quarrying and aggregate production

Sand and gravel screening

Recycling and waste management

| Parameter | Specification Options |

|---|---|

| Aperture Shape | Rectangular (Slotted), Square |

| Aperture Size | Customizable (e.g., 1mm x 10mm to 10mm x 100mm) |

| Wire Diameter | 2mm - 12mm (depending on application) |

| Mesh Type | Flat Top, Double Crimp, Slotted Flat Wire, Slotted Crimped Wire |

| Material | High-Carbon Steel, Stainless Steel 304/316, Manganese Steel |

| Surface Treatment | Plain, Hot-Dip Galvanized, Powder-Coated |

| Panel Size | Customizable (e.g., 1m x 2m, 1.2m x 2.4m) |

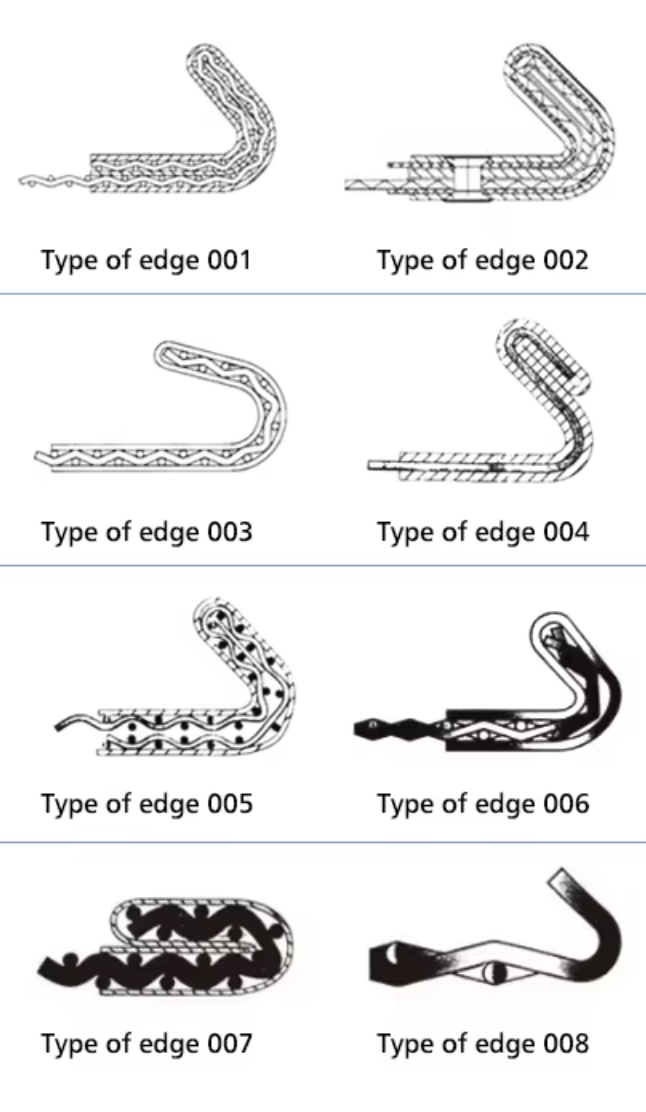

▼Type of Edge

To ensure optimal condition during transit and storage, we employ robust packaging methods:

Wooden Crates/Pallets: Screens are securely mounted on wooden pallets or crated to prevent bending or damage.

Weatherproof Wrapping: Each unit is wrapped in waterproof and anti-corrosive materials to protect against moisture and environmental damage.

Clear Labeling: All packages are labeled with product specifications, batch numbers, and handling instructions for easy identification.

Custom Packaging: Available upon request to meet specific logistics or handling requirements.

Expertise & Innovation: With years of specialization in mining screening solutions, we leverage advanced manufacturing technologies to deliver products that outperform industry standards.

Customization Capability: We provide tailored solutions—including aperture size, wire diameter, material, and panel dimensions—to meet unique operational needs.

Quality Assurance: Our products undergo rigorous quality checks to ensure durability, performance, and compliance with international standards (ISO, ASTM).

Competitive Pricing: As a direct manufacturer, we offer high-quality mining screens at competitive prices without compromising on reliability.

Global Logistics Support: We have extensive experience shipping worldwide and collaborate with trusted partners to ensure timely delivery and seamless supply chain integration.

Technical Support: Our team offers end-to-end support, from product selection and installation guidance to after-sales service, ensuring optimal performance and customer satisfaction.

Contact Us Today!

For a detailed quotation, technical consultation, or custom product requirements, reach out to our team. Provide your material type, aperture specifications, and operational conditions for a tailored solution. Let us help you enhance your screening efficiency and productivity!

Product consultation

WhatsApp

WhatsApp