Description: Wire mesh is typically installed in wall plaster layers (including junctions between different wall materials) and roof fine-aggregate concrete leveling courses for crack resistance. The selection of specifications and models varies depending on the application location, with specific characteristic

Model No.:JH5767WM

Model No.:JH5767WM Supply Nature:Factory Direct

Supply Nature:Factory DirectPRODUCTS

NEWS

Product Details

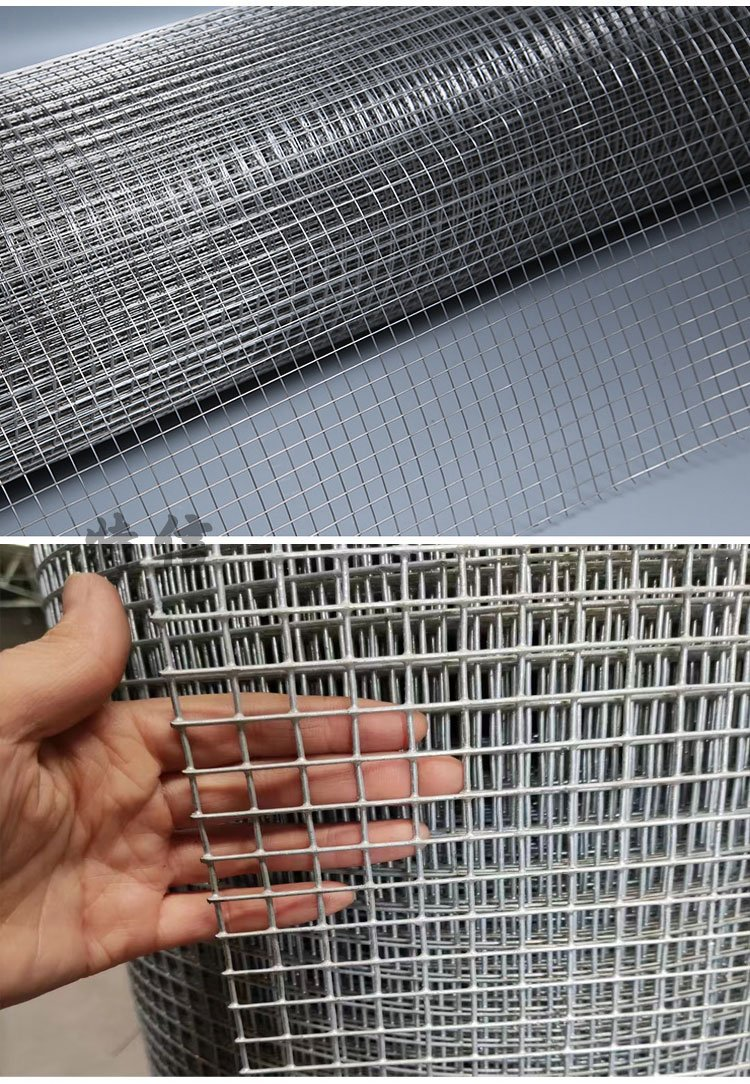

Wire mesh is typically installed in wall plaster layers (including junctions between different wall materials) and roof fine-aggregate concrete leveling courses for crack resistance. The selection of specifications and models varies depending on the application location, with specific characteristics as follows:

I. Wire Mesh in Wall Plaster Layers (Including Junctions Between Different Walls)

Purpose: To prevent cracking in the plaster layer caused by differences in wall material (e.g., masonry vs. concrete, different masonry types), thermal expansion/contraction, or drying shrinkage. It also enhances the bond stability between the plaster layer and the substrate.

Common Wire Diameter: The common range is 0.4–0.8 mm, with 0.5–0.6 mm being the most frequently used.

Mesh Aperture: Common sizes are 10mm×10mm, 15mm×15mm, and 20mm×20mm, with 15mm×15mm being predominant. For high-finish projects requiring superior surface flatness, a 10mm×10mm aperture can be selected to provide finer, more dense restraint for the plaster layer.

Applicability:

At junctions between different materials (e.g., masonry walls and concrete columns/beams), a 0.5 mm wire diameter generally suffices for crack resistance.

For exterior wall plaster on insulated walls where wind load resistance is a consideration, a wire diameter of 0.6–0.8 mm can be selected.

Material: Hot-dip galvanized wire mesh is preferred (zinc coating ≥ 80 g/m²). For damp environments (e.g., bathroom/kitchen exterior walls), a heavier zinc coating (≥ 120 g/m²) is recommended.

II. Wire Mesh for Roof Fine-Aggregate Concrete Leveling Courses (or Protection Screeds)

Purpose: To resist cracking in the fine-aggregate concrete (typically 40–60 mm thick) induced by thermal stress (diurnal temperature variation, seasonal changes) and drying shrinkage. It enhances the concrete's integrity and prevents cracking and leakage in the leveling course.

Wire Diameter: The common range is 0.8–1.2 mm, with 1.0 mm being predominant.

Mesh Aperture: Common sizes are 15mm×15mm, 20mm×20mm, and 25mm×25mm, with 20mm×20mm being the most common.

Applicability:

A 20mm×20mm aperture is suitable for most roof applications.

When the concrete thickness is relatively thin (within 40 mm), a 15mm×15mm aperture can be selected to prevent the wire mesh from being exposed and rusting.

Material: Hot-dip galvanized wire mesh is preferred (zinc coating ≥ 100 g/m²). Cold-drawn low-carbon steel wire is often used for galvanizing in this context (offering higher strength).

Installation Method: The mesh must be placed centrally within the concrete (approximately 10–15 mm from the surface). Lap joints should be ≥ 100 mm to ensure the overall continuity of the concrete leveling course.

Wall plaster mesh focuses on "reinforcing thin plaster layers," featuring relatively finer wires and moderate mesh sizes.

Roof screed mesh focuses on "enhancing the overall crack resistance of the concrete," featuring larger wires and slightly larger mesh sizes, with higher technical requirements for corrosion protection.

Procurement Note: When procuring, clearly specify details such as the exact specification, wire diameter, and galvanization type (hot-dip or cold-dip galvanized, specifying the minimum zinc coating weight if required) to the supplier, as these factors significantly impact the final cost.

Product consultation

WhatsApp

WhatsApp